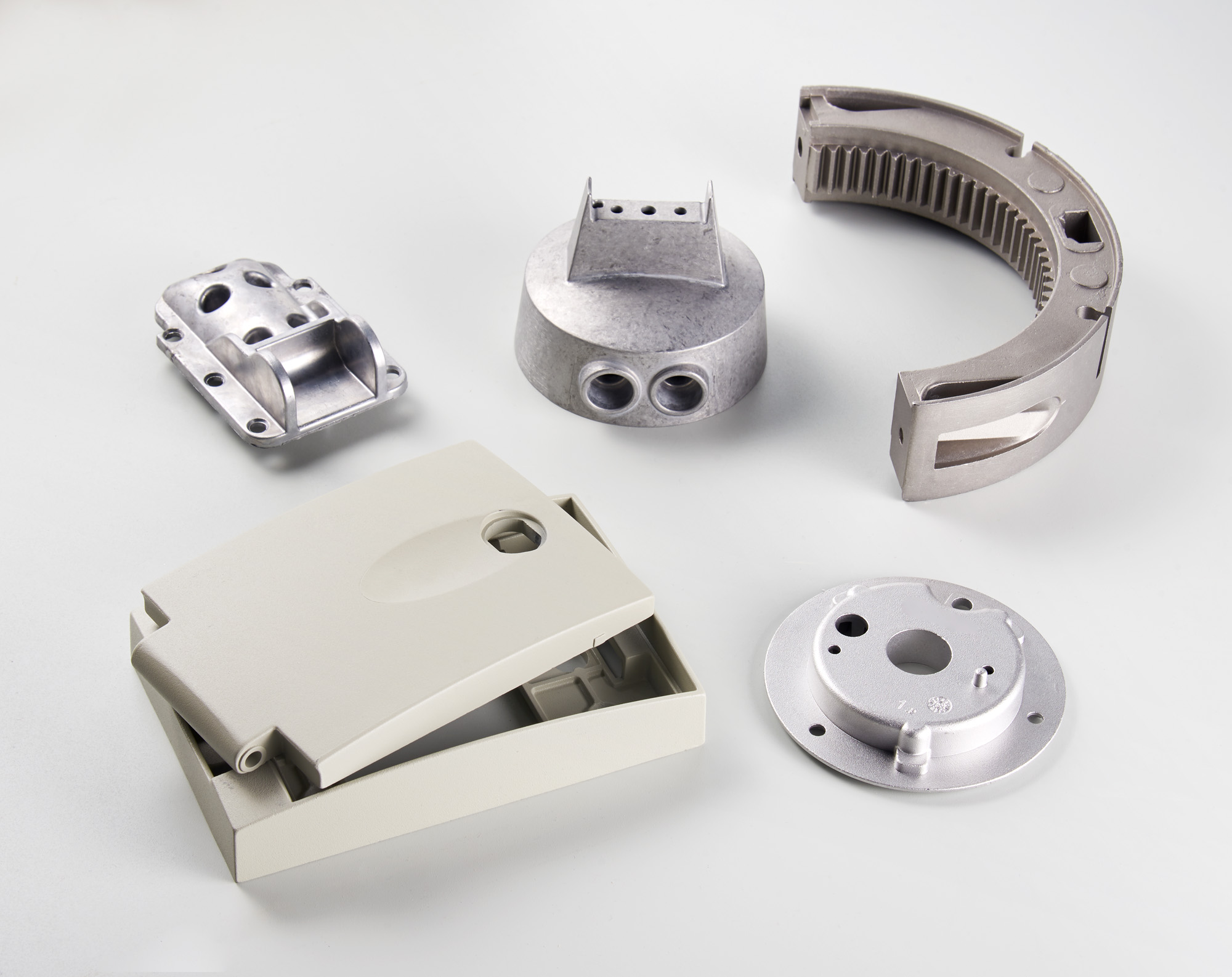

ALUMINUM Die-Casting

The reasons for aluminum die-casting:

- Ideal for medium and large series production

- Good surface finish associated with high aesthetic qualities

- Excellent mechanical characteristics

- Excellent predisposition for any mechanical processing

- Corrosion resistance

- Optimal stiffness and strength-to-weight ratio

- Complete recyclability

- Low production/raw material costs

To meet the needs of its customers, since 2018 the company has introduced aluminum die-casting, first with a new robotic production cell with a clamping force of 550 TON and later, in 2021, with an additional 650 TON production cell.

The characteristics of aluminum associated with efficient systems permits the production of articles for many application sectors allowing the company to produce components that are used in the electronics, lighting, accessories for doors and windows and furnishing accessories, just to name a few.

Main characteristics

One of the best technical characteristics of aluminum is undoubtedly its lightness.

Just consider that for the same volume, aluminum weighs about 1/3 of copper and steel.

In addition, the ductility and malleability make it an easily workable material and suitable for undergoing machining processes both at low and high temperatures.

Quality

Recyclability is one of the main advantages of aluminum.

Few materials in the world can be 100% recycled infinite times without losing the original qualities.

They remain unchanged indefinitely, even as a result of numerous recycling phases even when from being primary aluminum the metal becomes “recycled aluminum” or “secondary aluminum”.

Costs

The die-casting of aluminum, performed with the latest generation plants, allows to realize the production of small, medium and large quantities, allowing the correct amortization of the cost of the mold and its wear over time.

Die-Casting

Zamak

Design and construction of the

Mold

Cleaning

of components